To transform the potential of green hydrogen for energy resilience from concept to manufacturing, engineering service providers look to solutions that can tackle the complexity of these projects and build trust with their customers. For this large-scale project that includes a wind farm, battery energy storage (BESS), hydrogen production, and ammonia synthesis, Mintal used an ETAP digital twin in this feasibility study. The engineering team for this project knew that by choosing ETAP, the customer would benefit from end-to-end digital continuity from modeling simulation through the full lifecycle of their manufacturing operations.

Mintal Hydrogen Energy Technology Co., Ltd. is an international hydrogen energy technology company, providing zero-carbon solutions that utilize new energy direct-coupling technology to manufacture environmentally-friendly products. With the support of quality shareholders and partners, Mintal has developed an advanced business model and is committed to being a leading provider of technological energy solutions. The company also co-founded the International Hydrogen Energy Center to promote global cooperation, leveraging its network and scientific resources to implement integrated wind-solar-hydrogen-ammonia projects for the production of green fuels and to demonstrate zero-carbon steel production using green hydrogen as a reductant.

Location: Baotou, Inner Mongolia, China

Year: 2024

Objectives and methods

Renewable Power Optimization and Proactive Operations Strategy

- Develop a phased approach to simplify the complexity of the project

- Identify solutions that integrate power and process systems to verify reliability of the design within a unified digital environment

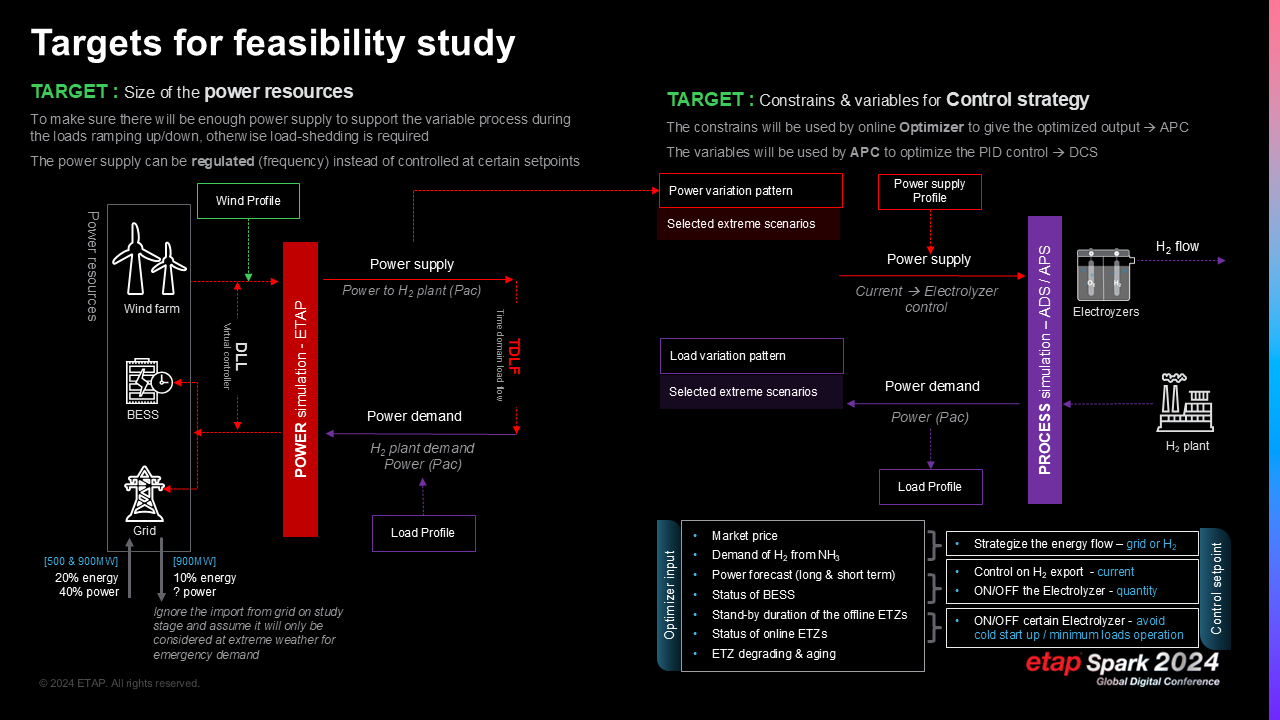

- Optimize sizing for wind capacity and battery storage for best economic return

- Propose cost-saving strategies for later phases, including the detailed design of the project and for real-time operations of the manufacturing facility

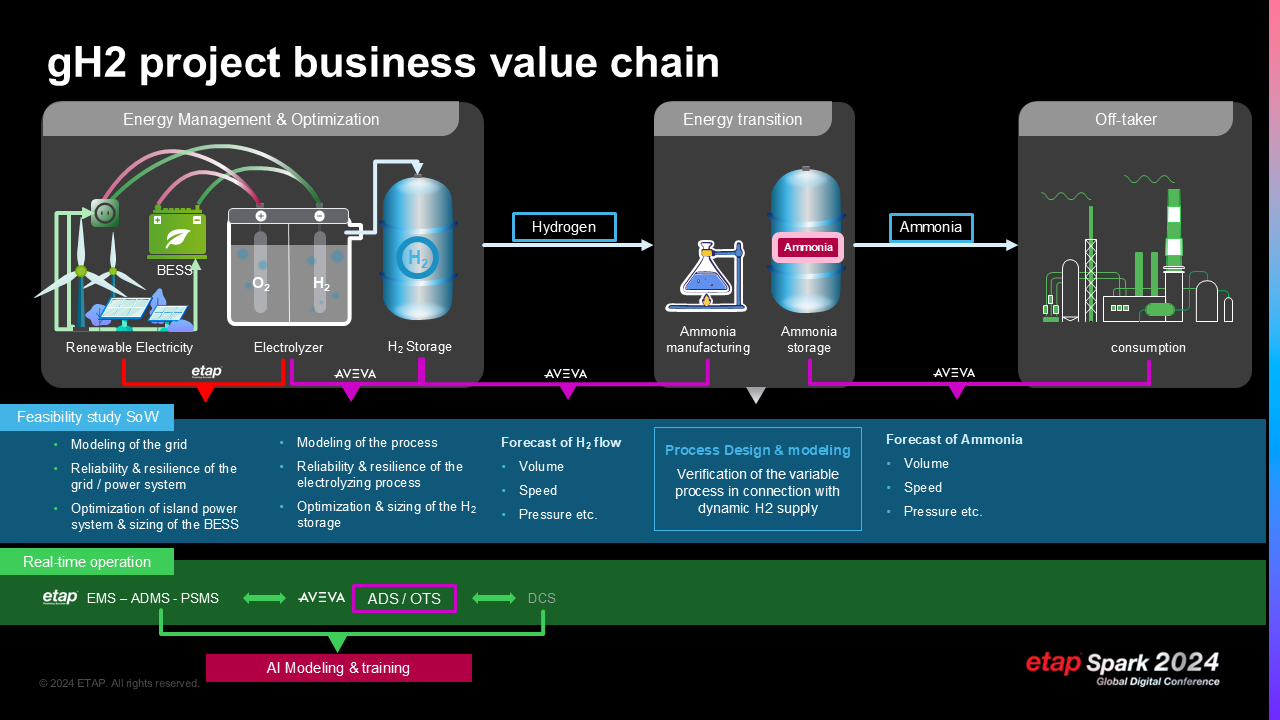

Mintal Hydrogen Energy Technology Co., Ltd. embarked on the planning for a 1.4-GW green hydrogen (gH2) and ammonia production facility - the first of its kind in China, to be located in Inner Mongolia. The investment for this project was approximately 1.2 billion USD. To support the green energy transition in China, the 1st phase capacity plans to produce 1,800 tons of g-ammonia daily, and 300,000 ton gH2 annually. Mintal exploried software solutions for power and process management, and initiated an end-to-end process optimization feasibility study for the project.

To simplify the work of the feasibility study, the Engineering Services Team at Schneider Electric recommended a three-phase approach:

- Integrated Power Generation – Modeling and managing the wind farm, BESS, and backup generation to ensure reliable power output and transmission

- Grid Transmission – Managing local grid constraints (export limited to 20%) while transferring 80% of generated power through a 70 km line directly to the hydrogen and ammonia plants

- Chemical Process – Controlling hydrogen and ammonia manufacturing, optimizing ramp-up and ramp-down responses to match variable renewable generation

This case study focuses on the comprehensive planning accomplished in Phase 1 to study the reliability of the power generated from renewable sources and transmission to the facility, while also looking ahead to the future phases.

Products used

ETAP Power Simulator, to model and simulate the electrical power system including generation, islanded operation, storage systems, performing steady-state and dynamic analyses for load forecasting, reliability, optimization and resilience. Notable features used include:

- Unified Electrical Digital Twin – To build and analyze a virtual representation of the proposed electrical network, including BESS

- Microgrid Analysis and Virtual Controller – To include the wind farm manufacturer equipment in the analysis

- Time Domain Load Flow (TDLF) – To simulate the behavior of an electric power system over time

By using ETAP, the engineering team was able to design, optimize, and test the performance of various generation contingencies and loading variations to allow for faster and validated field deployment.

As well, for the process domain, AVEVA was used to model the electrolyzers, hydrogen storage, and ammonia synthesis. The integration of ETAP and AVEVA via data exchange and Open Platform Communications (OPC) connectivity created a comprehensive end-to-end digital twin covering power, hydrogen, and ammonia manufacturing

What we delivered

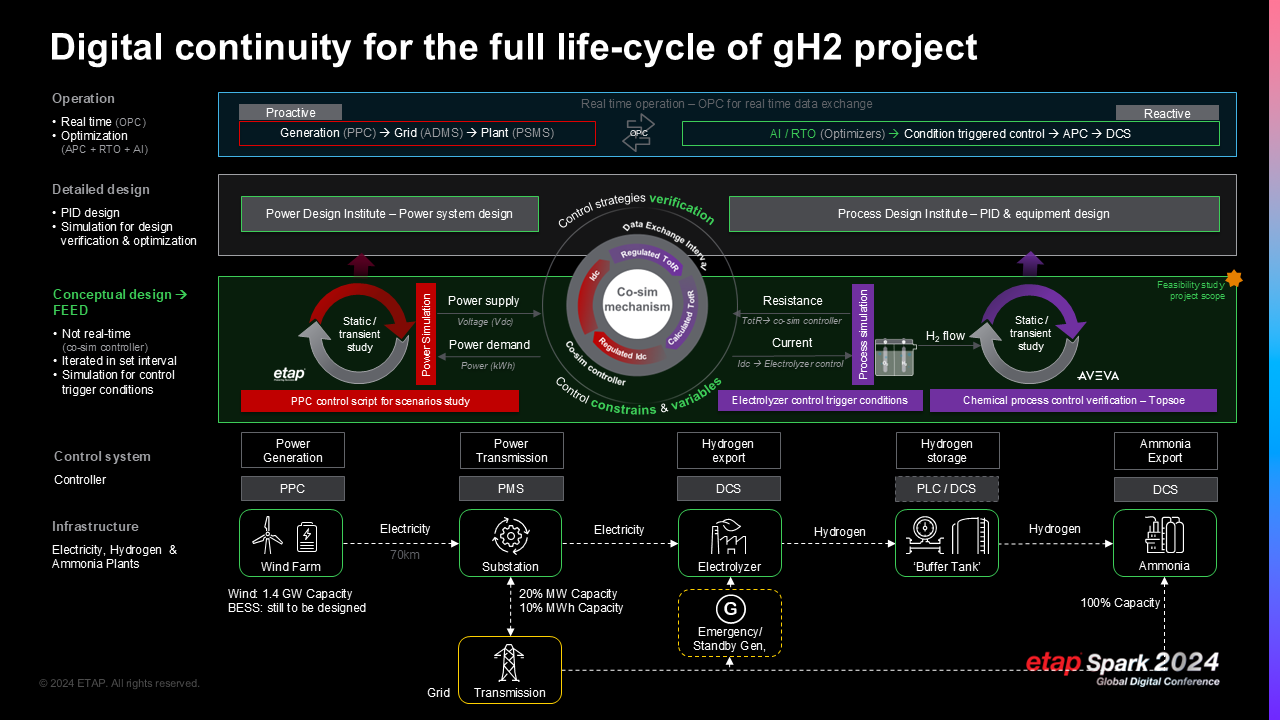

An end-to-end solution for the complete power system to support the project through all stages, from design to operations.

- Feasibility Study (Offline Simulation)

- Preliminary sizing and optimization of renewable and process systems

- Verification of control strategies between power and process domains

- Detailed Design & Engineering

- For the design phase, for detailed studies and validation

- Optimization of electrical and process systems for construction readiness

- Operation & Maintenance (Real-Time Control)

- Deployment of ETAP Energy Management System (EMS), ETAP Grid™ and Power System Monitoring & Simulation (PSMS)

- Integration with process-side systems (DCS, APC) via OPC for unified control and visibility

- Data-driven AI virtual operator to optimize load-generation coordination dynamically

The extensive capabilities provided by ETAP, including seamless transition to real-time operation control, helped the engineering service provider build a long term relationship of trust with the customer.

Outcomes

Lifecycle digital continuity from concept through operation

- Simplified the study for this unique and complex project through development of a digital twin for a phased approach to power system analysis, detailed design, and operations

- Enabled the accurate sizing of the renewable power and storage to reduce costs and ensure resiliency

- Ensured the best economic return through co-simulation of power and process, breaking down interdisciplinary barriers to verify the process

- Project is prepared for the future by using analysis data from model simulation to develop AI-enabled virtual operator tools for load forecasting

3

Videos

How Mintal optimizes green hydrogen projects using ETAP electrical digital twin technology

This case study focuses on a green hydrogen project that applied a digital twin solution. The project is a 1.4 gigawatt wind farm in China, involving green hydrogen and ammonia manufacturing, with an estimated investment of $1-2 billion. The customer recognized the need for a software solution to optimize their processes and was looking for comprehensive coverage from power management to process management. The project's objectives included sizing optimization to reduce CapEx costs, process verification and optimization, and digital tools for control system specifications and electrolyzer selection. The digital continuity and unified digital solution offered by Schneider Electric encompassed feasibility study, detailed design, and future operation and maintenance stages. The project's complexity required linking power and process data, utilizing ETAP and AVEVA software solutions for modeling and simulation, and employing digital twin technology for process control. The proposed approach included utilizing ETAP for energy transition engineering, emphasizing the value of ETAP software applications, and leveraging software services to ensure the success of the implementation. The study also highlighted the value of digital continuity and building trust with the client to ensure the success of the project.

Solutions

Packages/Products

- Analysis

- Asia

- Design

- Energy & Chemicals

- Engineering Consulting

- ETAP

- Manufacturing

- Renewables

- Simulation